Diary: Rotary Racer 9 Development

2014-10-04: Updates

The team have been very busy over the past few months. We've been to a number of races (race reports can be found at Race Reports) and also been developing the car :)

|

After Tom managed to squash our new head fairing at Merryfield, we decided to make some new ones ready for Dunsfold. The aim was to find a material that was fairly flexible (to help drivers get in and out of the car quickly and safely) but would also hold its shape whilst in the car. The younger members set to work tearing apart old school folders (a tip from Cullimore Racing) and shaping them to the car. About four different head fairings were used, and when tested at Dunsfold, they were very succesful! |

|

|

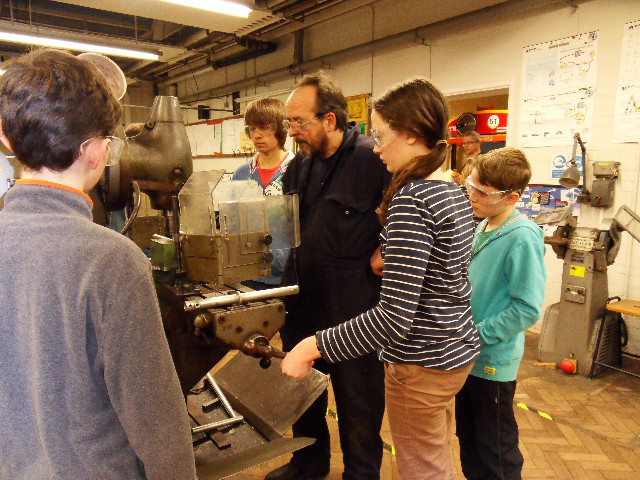

Another issue that we found was that the rear stub axle had been slightly bent... After Merryfield we set to work fixing it, breaking out the old rear stub axle and trying to make a new one with the school lathes. It was also pretty fun drilling into the car! (See picture) |

|

|

Just after Merryfield, we also decided to make a new cockpit edge. This would make the cockpit slightly narrower from the sides and the back, increasing aerodynamics but not proving to be an issue when getting out of the car. This new cockpit edge was made out of plywood and lined with foam. Unfortunately it wasn't ready in time for Dunsfold but it did prove to be a hit at Castle Combe! |

|

|

This year we also decided the car needed a bit of scrubbing up and we decided to treat it to a paint job. Nothing exciting again, only white, but the car does look much better! |

|

2014-06-05: Getting ready for Goodwood

With only a few weeks to Goodwood, work was well under way to make sure the car was finished.

- We've been testing out different polyfilla types to cover all those scrapes that were caused at the 2013 final (thank you Ben...) and have decided on using a lightweight filler. This has been used to cover the gaps, sanded down, and applied again to try and get the smoothest surface possible. A splash of paint has also been added to the car to cover up these gaps.

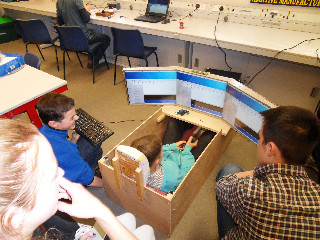

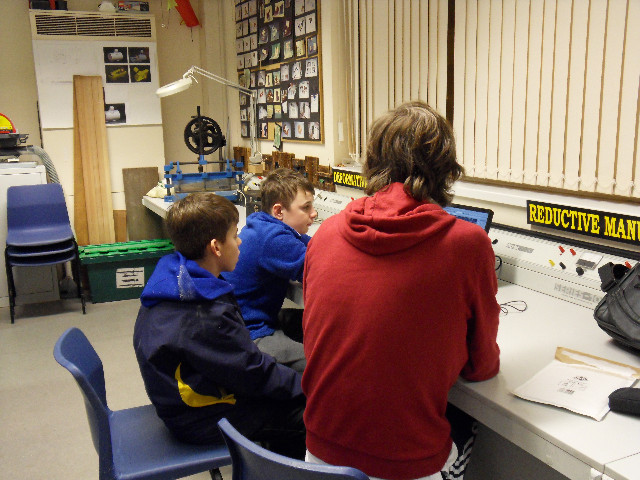

- We've finally finished the driving simulator! Well, we say finished but what we really mean is that it now works to a reasonable level :) All the members have had great fun racing against cars such as Zebedee and Viridity, battling against the over sensitive steering and trying not to turn too tightly as this results in nice spins off of the track... You can see a video of the driving simulator at work here: First Go in the Driving Simulator

-

The F24+ crew have carried out some battery tests to work out the current they will be able to withdraw from the batteries in the new 60 minute format. This data is going to be used in our simulator to decide on the best gear to use on each race day.

- The F24 drivers have had a few vital pitstop practices to try and minimise the time it takes to change driver. It's improving slowly, but don't expect anything amazing at Goodwood! It'll take a lot of practice to get it down to the old 40seconds we used to have :)

- The drivers also had a driver meeting to discuss race tactics for the day (sounds much more impressive than it is...). Hopefully everything will go to plan at Goodwood!

Good luck to everyone going to Goodwood this weekend, and we hope to see many of you there! :)

2014-02-24: The Speed Controller Works !

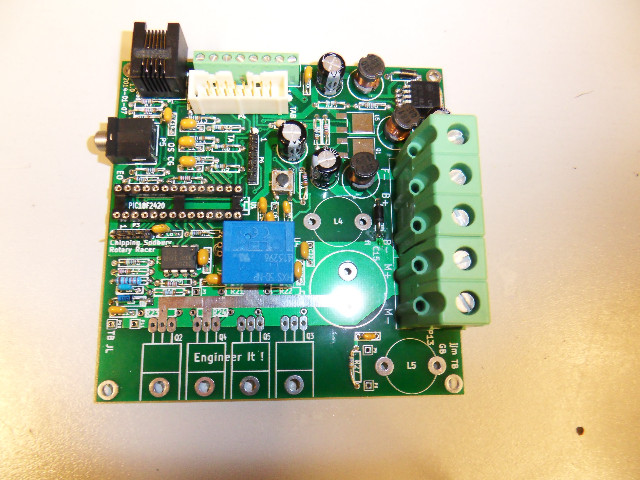

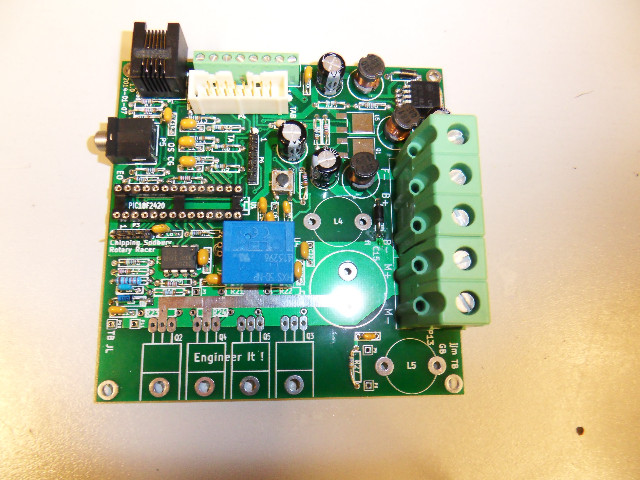

The new speed controller was tested with a bench top power supply. Louise wrote a few PicAxe Basic test programs to test the various functions including the LED, the motor output and the fan outputs. There was first a problem with communicating with the PC, a resistor value change was needed, but otherwise all looks like it is working.

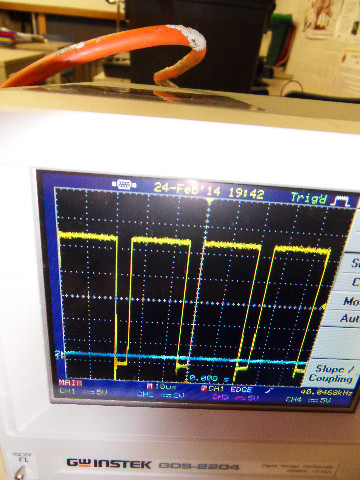

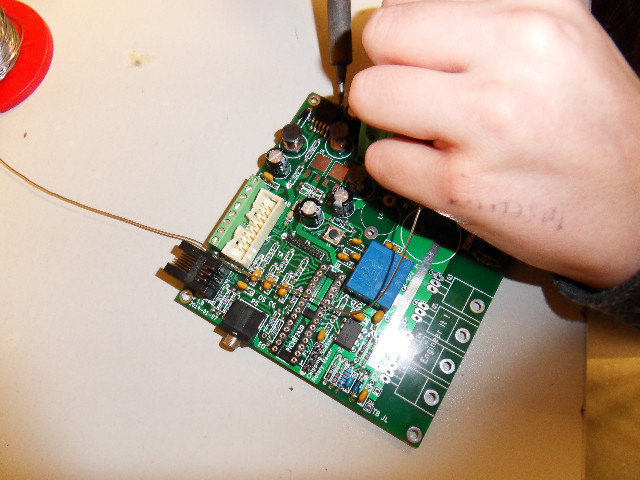

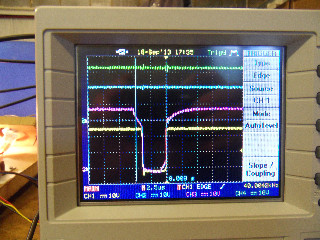

Then Louise and Becky put the speed controller through its paces using our simple motor/load test rig. The speed controller was connected up and drove the motor to full race power and it didn't blow up ! The switching waveform was looked at on an oscilloscope, looks good but a bit of ringing on MOSFET switch on to be investigated.

|

|

|

|

Meanwhile we had just booked for the seasons races and just realised that the Goodwood test day is only a few weeks away and the car was in not fit state to drive. So some frantic work in getting it back together for the test day commenced.

|

The plywood wheel rim had to be reattached. This was rubbing during the 2013 final losing us precious speed. |

| The new speed controlled had to be fitted. So new mounting holes had to be drilled for this. |

|

|

All teams at CSS were hard at work. This is one room with two teams working on their cars. Three other teams in adjoining rooms were hard at work at the same time. It is a typical, hectic before season Monday GP night! |

2014-02-17: The GpSpeed controller takes shape

Over the last few Monday seesions more soldering of the GpSpeed controller toolk place, it is now just about complete.

|

|

|

|

Work on the GpDrivingSimulator was also going on along with the new joystick with lathe and milling work.

2014-01-27: Work continues

development of the GpDrivingSim continues. We have managed to get the 3D model of RR9 into the simulator, not quite right yet spot the mistakes :)

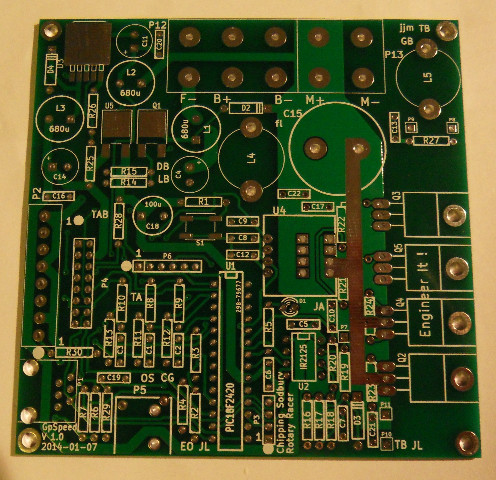

The GpSpeed new Greenpower speed controller PCB's arrive from production.

|

The GpSpeed new Greenpower speed controller PCB's arrive from production. They look good. Now we just need to solder all of the components to it. |

|

|

Louise is in charge of the building. All of Rotary racers team members soldered some components in as well as a few from the other Chipping Sodbury teams. We are building the first borad for RR9. This will be tested to make sure all of it works and then a further 3 boards will be made up by the other Chipping Sodbury teams. |

|

|

There are a lot of components to go through. The resistors purchased were a bit small and reading the colour bands were difficult. Meanwhile other work on the GpDrivingSim and the car itself was going on. A new steering joystick was being made as we had some much shorter team members this year. |

|

|

|

2014-01-23: Tracking the GP Speed

The basic Speed Controller circuit design has been completed, now it is time to track out the PCB. All young team members from Rotary Racer did a stint as well as members from TPM, Chain Reaction and Alderney Express. Luckily Gareth was back from University for the Christmas holidays and so helped out showing them how to use the PCB CAD tool and the basics on tracking a 2 layer PCB.

|

|

|

|

|

|

The PCB tracking was finished and the design sent out to a PCB production house to produce the prototype boards. We now have to purchase the components. When they get back the pupils from all of the teams will be able to assemble the components on them. There is a plan for some of the pupils to make up a building instruction sheet to help other teams build them

2014-01-21: The GpDrivingSim driving simulator work is started

Amongst other work including fitting the wooden wheels to the older RR8 car and working on RR9's joystick we started work on the Greenpower driving simulator. We have a lot of new team members this year who haven't driven, so one idea is to make up a driving simulator. We tried out some simulators at the Autosport show to get some ideas.

|

|

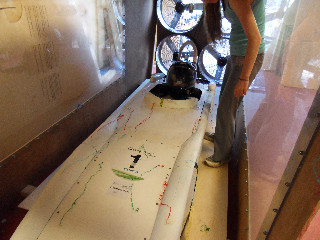

We were lucky in that there was an old 3 screen monitor hanging around. This was coupled to an old PC with a 3 monitor graphics board bought second hand and we had the basis for the computer electronics of the simulator. The idea is to make up a mockup Greenpower car, like RR9, with a joystick control. Tristan and Tom played around with setting up the Speed Deams software and tring to get the Joystick control to work. Joe designed a basic wooden, car sized box to take our hammock seat from RR8 and with Becky and others started cutting this out of plywood.

|

|

|

|

Work then started on how to get the Joystick steering, throttle and brake movements into the computer. We have a cheap PC USB joystick unit which we intend to dismantle and connect up to some potentiometers mounted to the real joystick we will build into the car.

Tristan is looking at the software. We are trying Speed Dreams and Torcs (Open source free software). First thing to do is to get the 3D model of RR9 into the simulator and then change the Physics parameters of the car to more closely match that of RR9 (mind you I think there will be a "turbo" version of RR9 as well !). After that we will see if we can make up a track like Goodwood, there are lots of ideas such as sound, vibration etc., but we will see how time goes...

2014-01-13: After Christmas

We are getting back into it after the Christmas holidays. Quite a few projects planned and going on. The first is to tidy up around the place as there are bits everywhere and it is hard to work. One of the main items was what to do with our older RR8 car. Rather than scrap it we decided to try and put it up for show on a high platform in the DT rooms. Unfortunately, amougst other things, it did not have any wheels. So some of the pupils made some wooden wheels from ply (no they won't be used in a race :) ).

|

|

The next project is a new electronic speed controller for RR and 3 other Chipping Sodbury school teams. Some work on tracking out the PCB for this was done. Some info on this is at:

- http://www.greenpower.beamweb.co.uk/groups/electronics/GpSpeed/index.html

- http://www.greenpower.beamweb.co.uk/diary?cmd=view&id=5

|

|

There is also some work on the car going on to fix the bodywork from the crash at the Final and to extend the joystick steering column for our new shorter team members. Also some research on the new GpSim Greenpower car driving simulator has started.

|

|

2013-12-02: 2/12/13

Over the past few weeks we've been busy coming up with the ideas of what we're going to be doing over the next few weeks. Here's a quick update:

- First we had a meeting (fun, fun, fun) to decide what we're going to be doing this year on the car. A few ideas include using the raspberry pi for the new battery charger and fixing the car for the next season!

- Next we had a session of building and replacing as students started working on a new driving simulator to try and help our new drivers gain some vital experience before letting them loose on the track.

- We've started making some wood wheels for the old Rotary Racer so we can put it on show in the Greenpower workshop.

- We've started trying to replace the front of the foam section for the car so it will be able to perform next season.

We'll try and keep you updated!

Rotary Racer :)

2013-10-12: Last touches before the final!

It's the last week before the final and everything is being modified and changed to try and make the car as prepared as possible for the big race!

A quick paint job, finishings of the new pit board and some work on battery leads!

|

|

|

|

|

|

2013-09-30: After Castle Combe

Castle Combe went very well for us. The car managed 118 miles even with 7 drivers and two new ones at that. Lap times were significantly up from the previous year with the older car. So all is going very well. Except, our main rival Dougal is going better ...

So we had a short meeting on what to do. The decision was made to try and make a few improvements before the final. The main items were:

- Improve the tail. The tail end was not quite the right shape. It was quickly made for the Goodwood race earlier in the year and was different from the original CAD design that had been VWT tested. Also our testing using the schools wind tunnel showed the air leaving the sides due to to tight an angle.

- Improve the behind head area. This has been a bit rough for years and the wind tunnel testing earlier in the year proved it to be bad. So we planned to try and make it a bit more aerodynamic using a thin plastic sheet as other teams have done.

- Improve the windshield and driver side area. This was disturbing the airflow to the sides of the driver were it was not needed.

- Use thinner battery cable to make installing the batteries a bit easier.

- Make new battery holding bars that will make getting the batteries out a bit easier.

- Make new vacuum formed rear wheel top covers. The moulds for these were about ready.

- More pitstop practice !

|

|

|

|

|

|

We had some extra time as we were showing the car at the school open day for new prospective pupils. Allowed some more work to be done. An few hours in a parents garage allowed some more bits to be done.

2013-09-19: After Merryfield

Merryfield went very well, we won :)

However there were some issues on the day with the power cutting out, and the speed controllers efficiency was a bit suspect (It was heating up). So some work.

| Improvements to the battery holding panels was carried out. |

|

|

The speed controller was getting a bit hot. The purple trace is the MOSFET gate drive voltage and the yellow the MOSFET output. The gate drive was taking a time to switch off and back on again leading to the MOSFETS heating up. Also the boost voltage needed for Gate operation was failing sometimes. A smaller Gate/Source capacitor helped the first and the second was due to a dodgy dry solder joint. Who did that one ... |

|

2013-06-24: Wind tunnel experiements

It was time to get down to some serious aerodynamic improvements, so out with the wind tunnel. Although the car was designed with the use of a software virtual wind tunnel, it is useful to look at the actual build with a real wind tunnel. This is useful for the fine detail.

|

|

|

|

|

|

Some detailed thinking and expierementation with the 3D CAD design and VWT. |

| Expieriementing with changing the angle of the behind area fairing as the air was seen to be leaving the surface. |

|

Some vides of the wind tunnel testing:

| Wind Tunnel Testing 1 | |

| Wind Tunnel Testing 2 |

The wind tunnel testing showed a number of areas for improvement. The main one was with the tail were the air was separating from the cars surface as the angles were to large. But there were many other areas that could be improved. Hopefully we will get around to implementing changes during the year or perhaps next year.

2013-06-10: The development starts

|

So the basic car has been completed and works well. Now it is time to get down to the development and optimisation of the design. The first thing is a team meeting. We normally have a team meeting after each race as we did at stages during the build. The normal thing we do is to go around everyone and ask for one bad thing that happend and one good thing. We then discuss these and anything else that comes up. Finally we write down an action plan of things we want to do (Well an A4 piece of paper with scribbled notes !). |

|

| Being a new car there where lots of things to discuss... |